#2 Defining Rust Back, Flash Rust, and Rust Bloom

Posted on 06. Mar, 2014 by Lydia Frenzel in Flash Rust

Back in 2005, Ray Weaver of SSPC Staff and Lydia Frenzel of Advisory Council co-authored an article to tell the difference between flash rust, rust back, and rust bloom. It never got published. Frenzel is posting this on the Flash Rust web site in March 2014. Look at this article and use the three flow diagrams that Ray Weaver developed. Frenzel will have further commentary. and provide the pictures that are referenced in the article. Frenzel will post a later commentary on the current SSPC and NACE definitions.

Weaver/Text/11-05 [revision 10-21-05]

Defining Rust Back, Flash Rust, and Rust Bloom

By Ray Weaver, SSPC: The Society for Protective Coatings, and Lydia Frenzel, Advisory Council

The only way to differentiate light, medium, and heavy flash rust is by interpreting the written descriptions given in the waterjetting standard SSPC-SP 12, Surface Preparation and Cleaning of Metals by Waterjetting Prior to Coating, or the words and pictures in SSPC-VIS 4, Guide and Reference Photographs for Steel Surfaces Prepared by Waterjetting. While searching for a test method to actually measure the amount of flash rust, it became evident that we first needed the definition. The immediate question to be answered was, “What is flash rust?” How is flash rust different from rust back or rust bloom? These three terms associated with the rusting of prepared steel have occasionally been used interchangeably. Unfortunately, the terms are not interchangeable, but their use in this manner is understandable because precise definitions that clearly differentiate among them do not exist.

The SSPC Protective Coatings Glossary (PCG) defines flash rusting as “rusting that occurs on metal within minutes to a few hours after cleaning is complete. The speed with which flash rusting occurs may be indicative of salt contamination on the surface, high humidity, or both.” For rust bloom, the PCG refers only to flash rusting; and there is no mention of rust back.

With the increased popularity of wet cleaning methods, these terms have evolved within the surface preparation industry to take on distinctive meanings. The PCG does not differentiate among these terms. Many in the surface preparation business know, or think they know, the differences; but it is very difficult to state them in a few words. It is always useful to state what something is, but it can also be informative to know what something is not. This article will define and illustrate rust back, flash rust, and rust bloom.

Since this project is in its infancy, the definitions presented here are not official SSPC definitions. They have not yet progressed through the entire SSPC ballot process. However, they have been thoroughly reviewed by the SSPC-NACE Joint Task Group TG 323 on Wet Abrasive Blast Cleaning and other experts in the waterjetting business.

Rust Back

Rust back is rust that occurs when freshly exposed bare steel is subjected to conditions of high humidity, moisture, or a corrosive atmosphere. It is the term used when steel cleaned by dry abrasive blasting or power tools begins to corrode. The time interval between cleaning and the development of rust back will vary greatly (from minutes to weeks) from one environment to another. For steel cleaned by wet blasting, rust that takes more than a few hours to develop is also called rust back.

If a degree of surface cleanliness is specified, e.g., SSPC-SP 6, Commercial Blast Cleaning, the steel surface must meet the specification immediately before paint application. If rust is visible before painting (i.e., rust back), the surface must be re-cleaned to meet contract cleaning requirements.

Residual chemical contamination on the surface can cause rust back to form quickly on the steel. Rust back initiated by contamination is usually tightly adherent. Even heavy rust back may not stain a rag when lightly wiped across the rusted surface. Rust back accelerated by contamination is not usually evenly dispersed across the surface, but it is heaviest in the most highly contaminated areas.

The key elements in categorizing rust as rust back are as follows.

• If the rust occurs within hours, it follows dry abrasive blast cleaning or another dry mechanical method of surface preparation

• For wet cleaning methods, the rust occurs several hours or days after the surface has dried

• Surface contamination may have contributed to the accelerated rusting

• The rust is tightly adherent and not powdery

• The rust is not usually evenly dispersed

flash rust or rust back Flowcharts 01 2008

Flash Rust

Flash rust is rust that occurs with any wet method of surface preparation as the surface dries or shortly thereafter. Flash rust occurs within minutes or, at most, hours. Wet cleaning methods include both waterjetting and wet abrasive blast cleaning. Steel that is cleaned with water can rust rapidly. The rate of re-rusting will depend on the purity of the water, the amount of oxygen dissolved in the water, the amount of ionic species left on the surface, the temperature, and the drying time. Flash rust is usually more or less uniform over large areas.

Non-uniform rust with areas of heavy rust or point sources of very dark rust usually indicates the presence of soluble salts on the surface and would be categorized as rust back, not flash rust, even if it occurs immediately after cleaning. While uniform flash rust may be an acceptable surface to paint (with an appropriate coating), more risk is entailed when painting over rust back. If the surface is cleaned by wet methods, uniform flash rust may not be a problem, provided the desired non-visible cleanliness (level of soluble salts) is achieved and verified by testing.

Flash rust can form quickly to change the initial appearance. It is not the rust itself, but the source of the re-rusting that is of concern, as inert iron oxides (rust) are used as pigments. Very dark, splotchy rust spots that appear to be isolated in localized areas usually indicate that ionic contaminants were left on the surface, usually in pits, under metal lips, or in crevices. These non-visible contaminants can be detrimental to coating performance. Uniform flash rust is considered inert and a sign of general steel oxidation. If the flash rust evolves into a loose powdery layer, coating adhesion and performance may be compromised. Conventional wisdom is that coating application over light, tight flash rust is acceptable. However, before applying a coating over any rust, it must be allowed by the specification, and the coating manufacturer’s instructions must be followed.

Visible flash rusting can be light, moderate, or heavy. The coating manufacturer must be consulted to determine the extent of flash rust that a specific coating can tolerate for the given exposure. Inhibitors can be added to the water to prevent flash rusting, but the coating manufacturer must be consulted to verify compatibility with the level of inhibitor used. The use of low conductivity water with the removal of all salts (as measured by field tests) will significantly reduce the amount of flash rust. The amount of flash rust also can be significantly reduced through forced air drying or the use of a vacuum shroud, which does not allow the water to remain on the surface as it is drying.

The key elements in categorizing rust as flash rust are as follows.

• The rust appears after a wet method of surface preparation

• The rust develops within minutes or hours

• The rust is somewhat uniform in color and texture over large areas

• The rust is tightly adherent if it is light, and powdery if it is heavy

• The rust is mostly the result of normal oxidation and not accelerated by chemical contamination

• The rust is usually evenly dispersed

NOTE: Pinpoint rusting that occurs during the drying phase of a thin coat of water-borne paint applied over blast cleaned steel is sometimes referred to as flash rust. This use of the phrase “flash rust” is not pertinent to this discussion.

Rust Bloom

Rust Bloom is new rust. Rust bloom is somewhat uniform rust spread evenly over a large section of the surface. Rust bloom may be either flash rust or rust back. Flash rust is a specific kind of rust bloom. Unlike flash rust, which only occurs after wet cleaning methods, rust bloom can occur on both wet or dry blast cleaned steel. Whereas flash rust develops in minutes or hours after cleaning, rust bloom can take days to develop, in which case it is a special case of rust back. The level of rust bloom that can be tolerated in a given environment must be determined by the coating manufacturer for each coating system. Rust bloom is simply uniform rust.

rust bloom rust back Flowcharts 02 2008

Cautions when Painting Rust Back or Flash Rust

It has been the practice in dry blasting to paint before rust back or re-rusting or rust bloom occurs. If the steel is contaminated with chlorides or other soluble salts, painting immediately after blast cleaning before the rust back occurs will trap the contamination between the paint and the substrate. The effect of this trapped contamination on coating life depends on the particular coating and on the exposure environment.

Light, moderate, and heavy levels of flash rust are characterized by the amount of loose rust on the surface. Applied paint must wet the substrate, not just the rust. Loose rust can be removed or brought to an acceptable level before applying paint by methods such as brushing, solvent (organic or water) wiping, or pressure washing. When pressure washing is used, the resulting surface will have a different appearance (color or hue) than the initial flash rust appearance.

The source of the rust (corrosion) process should be considered. Rust that is pure iron oxide can be benign, but caution must be exercised when the rusting is accelerated by salts.

Applying the Definitions- See the Flow Diagrams

Some things are difficult to quantify precisely, like how much water to add to the mortar mix for laying brick or how much milk to add to the mashed potatoes. After a little experience, you just develop a feel, and it becomes routine. Similar instincts kick in when categorizing the rust on a cleaned steel surface and then deciding what, if any, remedial action must be taken before applying the coating. In lieu of actual field experience, some surface characteristics will be illustrated that will help you accurately define a rusted surface and make sound decisions on coating it.

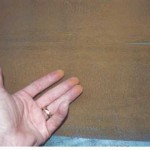

Figure 1 depicts a steel surface with rust bloom and light flash rust. The steel was cleaned to SSCP-SP 12, WJ-2, Very Thorough or Substantial Cleaning, which allows some paint to remain on the surface. When a hand was wiped lightly across the rust, almost no rust came off the surface onto the hand. In practice, a light cloth should be used for the wiping instead of a bare hand to avoid transfer of contaminants, especially salts, to the surface. Light flash rust is uniform and tightly adherent.

Light Flash Rust caused by Waterjet Cleaning. Looks like Rust Bloom. Fig 1

At first glance, the surface depicted in Fig. 2 looks very similar to the surface in Fig. 1; both show rust bloom. However, when a hand is wiped lightly across the surface in Fig. 2, powdery rust comes off easily onto the hand. The surface depicted in Fig. 2 was cleaned by waterjetting to WJ-1, Clean to Bare Substrate, where all rust and old paint are removed. The rust on this surface was uniform, loose, powdery, and evenly dispersed; i.e., it was heavy flash rust.

Medium to Heavy Flash Rust looks like Rust Bloom and caused by Waterjet Cleaning. Fig 2

New rust layer is dusty and wipes off.

- Medium Flash Rust looks like Rust Bloom.

The rust in Figs. 1 and 2 are mostly iron oxide with little soluble salt. Many coatings could be applied directly to the surface in Fig. 1 and give good protection. Before coating the heavily flash-rusted surface, as shown in Fig. 2, loose rust should be removed by brushing, water cleaning, or another suitable method. As was the case with light flash rust, tightly adherent rust can remain, as the nature of the rusting indicates an absence of excessive soluble salts. The coating manufacturer must be consulted to determine the degree to which the loose rust must be removed.

Rust Back looks like Rust Bloom during dry abrasive blast cleaning Fig 3

There is marine salt at top of the Rail car that contaminated the ricochet abrasive.

Figure 3 shows a rail car that was prepared by dry abrasive blast cleaning in a room where humidity and temperature were controlled. Normally, this facility could hold the blast on five cars before painting them. The rust bloom along the top half of the car occurred within an hour of blasting. This is rust back, not flash rust. First, flash rust occurs with wet blasting; dry blasting was used in this case. Second, the rust only occurred on the top half, even though the bottom half was subjected to the same environmental conditions. These factors indicate that the rust back was probably accelerated by salt contamination. The rust back is evenly dispersed, which indicates that salt was probably spread by contaminated abrasive. Another indication that the rust back was most likely influenced by salt is that where the rust was heavy, it could not be easily removed. It would be prudent in this case to perform a test for soluble salts, followed by possible salt remediation before painting.

Rust Back from dry abrasive blast cleaning (Fig 4)

This is the other side of the Rail Car.

The appearance is localized, dark black, splotchy.

Is it Rust Bloom by definition that Rust Bloom is “new rust?”

I call it BAD RUST!

The other side of the same rail car exhibiting rust back after dry abrasive blast cleaning is shown in Fig. 4. Here, rust back also occurred within an hour after blasting, but the rusting is localized, so it is not rust bloom. As with the rail car in Fig. 3, this localized rust back was most likely accelerated by salt contamination remaining on the surface in the bottom of pits.

Figures 3 and 4 show rust back caused by salt contamination after dry abrasive blast cleaning. The uniform rust back (rust bloom) in Fig. 3 was caused by contaminated abrasive, and the localized rust back in Fig. 4 was caused by surface contamination with localized salt corrosion cells. To apply paint over either surface involves high risk.

Before any meaningful dialog about rust back, flash rust, and rust bloom can occur, there must be agreement on the precise meaning of these terms. Understanding the root causes of the forms of rust described above will lead to informed decisions about which rusted surfaces can be painted and which ones should be re-cleaned, thereby avoiding unnecessary cleaning operations as well as costly coating failures.

Comments on this article are welcomed.