Pressure Washing and Excess Flash Rust

Posted on 16. Mar, 2009 by charles frenzel in NSRP

What Happens if there is too much Flash Rust prior to painting?

Prior to the application of paint, the substrate must meet the procurement specifications.

Prior to the application of paint, the substrate must meet the procurement specifications.

Typical field remediation includes:

Pressure washing

Broom brushing

Blowing off with pressurized air

Solvent cloth or dry cloth wiping

Vacuum

Upon polling contractors, it appears that pressure washing is the preferred practice. The appearance after pressure washing when the surface dries will be DIFFERENT; rust dust is washed away. Typically the surface has a darker appearance. The metallic sheen might disappear. The standard pictures in VIS-4 do not provide illustrations of pressure-washed surfaces.

Upon polling contractors, it appears that pressure washing is the preferred practice. The appearance after pressure washing when the surface dries will be DIFFERENT; rust dust is washed away. Typically the surface has a darker appearance. The metallic sheen might disappear. The standard pictures in VIS-4 do not provide illustrations of pressure-washed surfaces.

In the first two pictures, the substrate was pressure washed (ca 1000 psi) to remove the loose dust so that the substrate would meet a “light” flash rust requirement..

The substrate dried in a few minutes. Flat surface can take longer to dry.

INSPECT the AREA AFTER PRESSURE WASHING.

INSPECT the AREA AFTER PRESSURE WASHING.

Note that the loose dust is removed.

However, the stains on the right have remained.

The inspector, contractor, paint manufacturers, and owners (all the responsible parties in a coatings project) should note streaked areas and obvious runs.

In this example, the source of the water that created the original flash rust came from a hole in the ship that most likely had salts or oil and greases. Special attention should be given to those areas. Look to the project specifications as to what other inspections might be required.

In this example, the source of the water that created the original flash rust came from a hole in the ship that most likely had salts or oil and greases. Special attention should be given to those areas. Look to the project specifications as to what other inspections might be required.

At the right, notice that some areas are not washed, some have dried, and some are still drying.

Here are more pictures showing the same type of situation, where some areas are not yet washed, some are dry, and some are still drying.

Here are more pictures showing the same type of situation, where some areas are not yet washed, some are dry, and some are still drying.

Close up of area on right in picture above.

Close up of area on right in picture above.

To Repeat: the inspector, contractor, paint manufacturers, and owners (all the responsible parties in a coatings project) should note streaked areas and obvious runs.

In this example, the source of the water that created the original flash rust came from a hole in the ship that most likely had salts or oil and greases. Special attention should be given to those areas. Look to the project specifications as to what other inspections might be required.

A ll the defects can be seen. There are stains, but NO loose rust dust.

ll the defects can be seen. There are stains, but NO loose rust dust.

All the defects can be seen. There are stains, but NO loose rust dust.

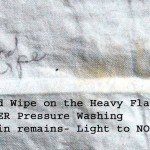

This is the result of the Brush Wipe Test on Heavily Stained & Heavy Flash Rust Area

Before Pressure Washing

Before Pressure Washing.

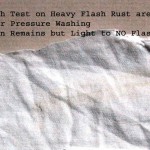

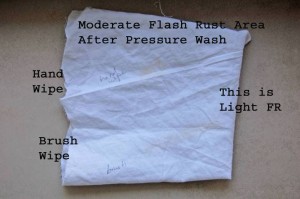

After Pressure Washing. Hand wiping test.

After Pressure washing. Brust test.

A direct comparison between hand wipe and brush test on pressure washed moderate flash rust indicates no differences.