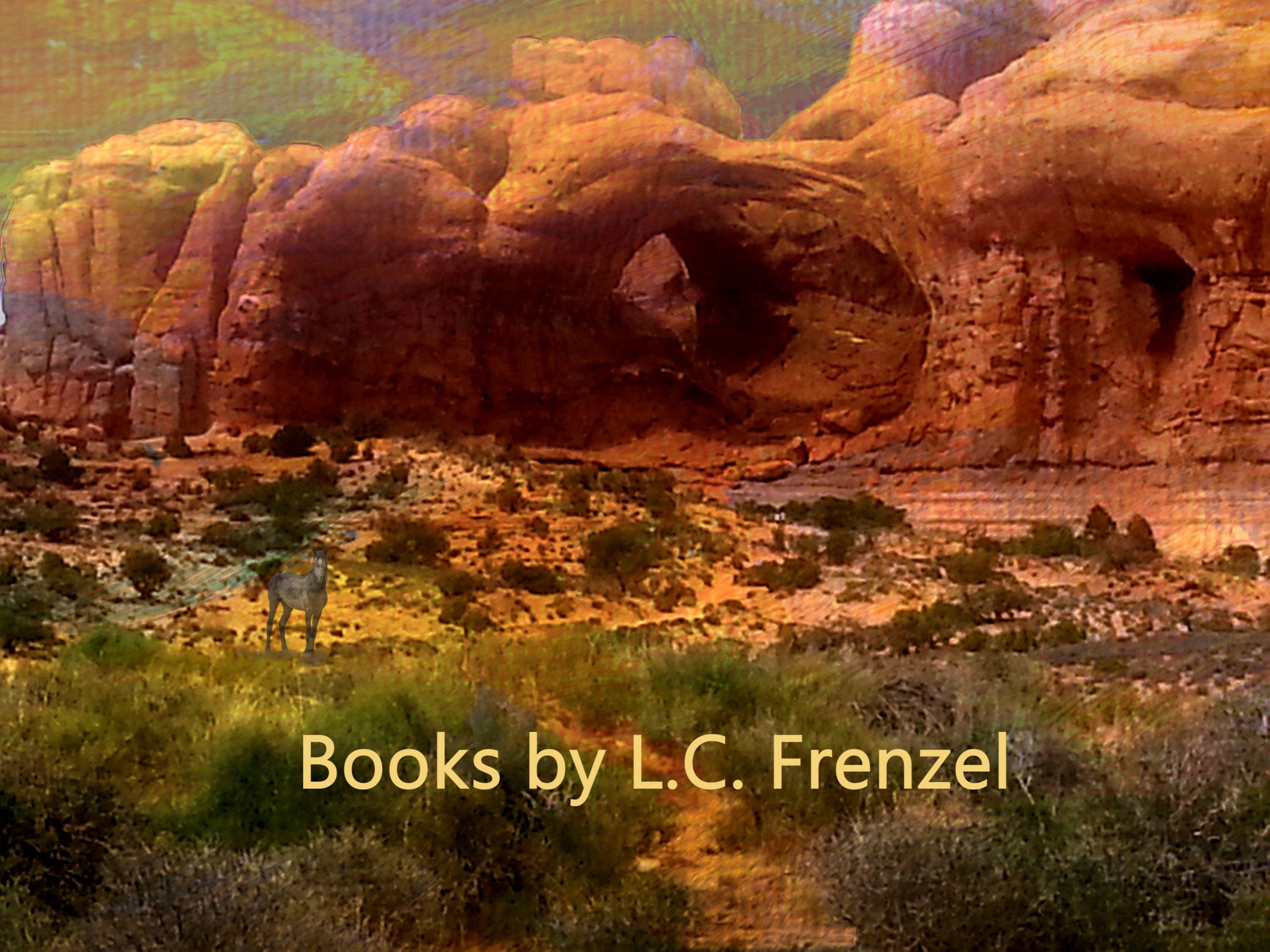

Discoloration

Posted on 15. Mar, 2009 by charles frenzel in NSRP

Discoloration

Brown or black discoloration remaining in pits is not the same as flash rust. Metals other than carbon steel can manifest discoloration as well.

USS Champlain CG 67 Example of Discoloration

San Diego 2002. Photo courtesy Y&T Consulting

There is no one single type of “flash rust.”

With the exception of stainless steel surfaces, any steel surface may show flash rust within 0.5 hour or longer, depending on environmental conditions, after cleaning by water. Flash rust has the appearance of rust bloom. Flash rust quickly changes the appearance of the cleaned surface and may be reduced or eliminated by physical or chemical methods. The color of the flash rust may vary depending on the age and composition of the steel and the time-of-wetness of the substrate prior to drying. With time, the flash rust changes from a yellow-brown, well adherent, light rust to a red-brown, loosely adherent, heavy rust.

The four sections were cleaned on the same day. They illustrate that the color and quantity can differ with different techniques.

There is no loose rust dust. Each area displays a little different version of light flash rust.

Upper left is WAB with soluble abrasive

Upper right is 15,000 psi without abrasive

Center left is WAB with coal slag (Black Beauty)

Lower right is 10,000 psi without abrasive.

This is about 3 hours after the cleaning processes.